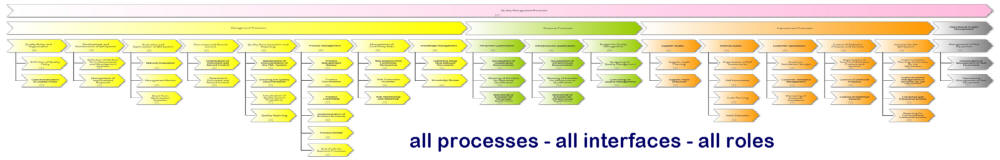

The new QM Process Library

Processes Management Resources Improvement Business Operational Quality Management

1. PDCA Cycle

Positioning of the process groups within the ISO 9001 PDCA cycle referring to the chapters of the standard.

2. Processes

2.1. Management Processes

2.1.1. Quality Policy and Organization

|

Interfaces Quality Policy and Organization

|

|

Integration to other ISO 9001-process groups and main information flows thereto

|

|

Definition of Quality Policy

|

|

Definition, formulation and documentation of the quality policy

|

|

Operationalization of Quality Policy

|

|

Operationalization and execution of implementation activities for the quality policy |

2.1.2.Development and Maintenance of QM System

|

Interfaces Development and Maintenance of QM System

|

|

Integration to other ISO 9001-process groups and main information flows thereto

|

|

Definition of Medium Term Maintenance and Development Activities

|

|

Definition of potential medium term activities for the future maintenance and development of the quality management in the company

|

|

Management of Improvement Proposals

|

|

Intaking of, evaluation of and relevant reaction to improvement proposals including feedback to the proposer |

2.1.3. Evaluation and Optimization of QM System

|

Interfaces Evaluation and Optimization of QM System

|

|

Integration to other ISO 9001-process groups and main information flows thereto

|

|

Maturity Evaluation

|

|

Diagnosis and evaluation of the maturity of the quality management system

|

|

Management Review

|

|

Definition of a structured portfolio of future developments of the quality management in the company based upon a complete review of the effectivity of the quality management system

|

|

Short Term Optimization Activities

|

Definition of potential short term optimization activities for the quality management in the company and as far as possible immediate implementation |

2.1.4. Document and Record Control

|

Interfaces Document and Record Control

|

|

Integration to other ISO 9001-process groups and main information flows thereto

|

|

Organization of Document and Record Control

|

|

Organization of processes and procedures for the life cycle management of documents and records needed to be controlled:

|

|

Operational Document and Record Control

|

|

Operational life cycle management of documents and records needed to be controlled:

|

2.1.5. Quality Documentation and Reporting

|

Interfaces Quality Documentation and Reporting |

|

Integration to other ISO 9001-process groups and main information flows thereto

|

|

Maintenance of Documentation of the QM - System |

|

Permanent actualization and further development of the documentation of the quality management system

|

|

Ensuring the Quality Documentation |

|

Ensuring of operational documentation of quality operations

|

|

Actualization of Quality System Procedures |

|

Provision of relevant reporting for the quality management

|

|

Quality Reporting |

|

Creation of relevant reporting for the quality management |

2.1.6. Process Management

|

Interfaces Process Management |

|

Integration to other ISO 9001-process groups and main information flows thereto

|

|

Process Management Review |

|

Continual validation and improvement of the procedures and methodologies of the company wide process management

|

|

Process Coordination |

|

Coordination of life cycles of company wide processes and ensuring friction free integration

|

|

Process Controlling |

|

Assessment of company wide processes by analysis of their performance indicators and deduction of improvement potentials

|

|

Implementation of Business Processes |

|

Design and implementation of new respective modified business processes according to the business requirements based upon the formal requirements of process management

|

|

Process Review |

Checking the company wide processes for problem areas on regular basis and introduction of necessary activities thereof

|

|

|

End of Life for Business Processes |

Controlled shut down of usage of defined business processes |

2.1.7. Management of Conformity Risks

|

Interfaces Management of Conformity Risks |

|

Integration to other ISO 9001-process groups and main information flows thereto

|

|

Risk Analysis from Conformity Perspective |

|

Analysis of criticality of products and services from conformity perspective

|

|

Risk Prevention Activities |

|

Activities against detected conformity risks including process and responsibilities thereto

|

|

Risk Monitoring and Reporting |

|

Management of risk avoiding activities (surveillance, triggering of corrective actions) and reporting thereto |

2.1.8. Knowledge Management

|

Interfaces Knowledge Management |

|

Integration with other ISO 9001-process groups and main information flows thereto

|

|

Gathering Know How Relevant Documents |

|

Structured collection and archiving of the knowledge of the (quality-)organization

|

|

Knowledge Review |

|

Review of the actuality of the knowledge management database |

2.2. Resource Processes

2.2.1. Personnel Qualification

|

Interfaces Personnel Qualification |

|

Integration to other ISO 9001-process groups and main information flows thereto

|

|

Actualization of Qualification Requirements |

|

Review of requirements to personnel qualification and triggering of adequate activities to ensure sufficient qualification in case of changed requirements

|

|

Planning of Activities for Personnel Qualification |

|

Planning of adequate activities to ensure sufficient qualification according to the quality requirements

|

|

Control of Activities for Personnel Qualification |

|

Control of execution and effectivity of adequate activities to ensure sufficient qualification according to the quality requirements |

2.2.2. Infrastructure Qualification

|

Interfaces Infrastructure Qualification |

|

Integration to other ISO 9001-process groups and main information flows thereto

|

|

Actualization of Infrastructure Requirements |

|

Review of requirements to infrastructure and triggering of adequate activities to ensure sufficient infrastructure in case of changed requirements

|

|

Planning of Activities for Infrastructure Qualification |

|

Planning of adequate activities to ensure sufficient infrastructure according to the quality requirements

|

|

Control of Activities for Infrastructure Qualification |

|

Control of execution and effectivity of adequate activities to ensure sufficient infrastructure according to the quality requirements |

2.2.3. Budget for Quality Management

|

Interfaces Budget for Quality Management |

|

Integration to other ISO 9001-process groups and main information flows thereto

|

|

Budgeting for Quality Management |

|

Planning of sufficient financial resources to fulfill the quality requirements and targets

|

|

Controlling for Quality Management |

|

Economic control of utilization of financial resources for the quality management |

2.3. Improvement Processes

2.3.1. Supplier Audits

|

Interfaces Supplier Audits |

|

Integration to other ISO 9001-process groups and main information flows thereto

|

|

Supplier Audits Planning |

|

Periodical and event triggered planning of supplier audits

|

|

Supplier Audits Execution |

|

Execution of scheduled periodical respective event triggered supplier audits according to the supplier audit planning |

2.3.2. Internal Audits

|

Interfaces Internal Audits |

|

Integration to other ISO 9001-process groups and main information flows thereto

|

|

Organization of Self Assessments |

|

Organization of the internal evaluation of the quality management system from inside the organization

|

|

Self Assessment |

|

Planned and event triggered internal evaluation of the quality management system from inside the organization

|

|

Audit Planning |

|

Periodic and event triggered planning of internal audits

|

|

Audit Execution |

|

Execution of scheduled periodical respective event triggered internal audits according to the internal audit planning |

2.3.3. Customer Satisfaction

|

Interfaces Customer Satisfaction |

|

Integration to other ISO 9001-process groups and main information flows thereto

|

|

Customer Satisfaction Surveys |

|

Proactive collection of information about the satisfaction of the consumers with the supplies of the company and introduction of necessary activities thereof

|

|

Customer Feedback Management |

|

Management of feedback (complaints and commendation) from customers and introduction of necessary activities thereof

|

|

Monitoring of Customer Complaints |

|

Monitoring of open customer complaints to enable necessary counter activities |

2.3.4. Control of Defective Products and Services

|

Interfaces Control of Defective Products and Services |

|

Integration to other ISO 9001-process groups and main information flows thereto

|

|

Organization of Control of Defective Products and Services |

|

Setup of processes, definition of responsibilities and documentation standards for the control of defective products and services

|

|

Control of Defective Products |

|

Ensuring that defective products are

|

|

Control of Defective Services |

|

Ensuring that defective services are

|

2.3.5. Activities for the QM System

|

Interfaces Activities for the QM System |

|

Integration to other ISO 9001-process groups and main information flows thereto

|

|

Implementation Planning of Activities for the QM System

|

|

Implementation planning for all registered activities for the quality management system regarding their interdependencies

|

|

Implementation Management of Activities for the QM System |

|

Management of implementation and monitoring of all registered and planned actions for the quality management system

|

|

Corrective and Preventive Actions |

|

Definition and triggering the execution of corrective actions for detected defects respective preventive actions

|

|

Reporting for Corrective and Preventive Actions |

|

Reporting and knowledge management for corrective and preventive actions |

2.4. Business Processes

2.4.1. Marketing and Sales

Customer specific process, hence documentation of the inputs from and the outputs to the quality management (interface)

2.4.2. Planning

Customer specific process, hence documentation of the inputs from and the outputs to the quality management (interface)

2.4.3. Production and Service Delivery

Customer specific process, hence documentation of the inputs from and the outputs to the quality management (interface)

2.4.4. Dispatch and Handover

Customer specific process, hence documentation of the inputs from and the outputs to the quality management (interface)

2.4.5. Customer Service

Customer specific process, hence documentation of the inputs from and the outputs to the quality management (interface)

2.4.6. Product and Service Development

Customer specific process, hence documentation of the inputs from and the outputs to the quality management (interface)

2.4.7. Procurement

Customer specific process, hence documentation of the inputs from and the outputs to the quality management (interface)

2.4.8. Logistics

Customer specific process, hence documentation of the inputs from and the outputs to the quality management (interface)

2.4.9. Operational Quality Assurance

Customer specific process, hence documentation of the inputs from and the outputs to the quality management (interface)

2.4.10. Finance and Controlling

Customer specific process, hence documentation of the inputs from and the outputs to the quality management (interface)

2.4.11. IT

Customer specific process, hence documentation of the inputs from and the outputs to the quality management (interface)

2.4.12. Facility Management and Maintenance

Customer specific process, hence documentation of the inputs from and the outputs to the quality management (interface)

2.4.13. Human Resources

Customer specific process, hence documentation of the inputs from and the outputs to the quality management (interface)

2.5. Operational Quality Management

2.5.1. Management of Test Equipment

|

Interfaces Management of Test Equipment |

|

Integration to other ISO 9001-process groups and main information flows thereto

|

|

Organization of Management of Test Equipment |

|

Organization of the lifecycle management of test equipment

|

|

Operational Management of Test Equipment |

Operational lifecycle management of test equipment |

3. Templates

The templates are linked to glossary entries and with process steps also (if appropriate).

-

Template Audit Plan

-

Template Audit Planning

-

Template Audit Protocol

-

Template Audit Report

-

Template Quality Management Manual

-

Template Quality Management Report

4. Checklists

The checklists are linked to glossary entries and with process steps also (if appropriate).

-

Checklist Improvement Register

-

Checklist Internal Audit

| Register free of cost and test the QM Process Library without obligation | |

|

|

|

Contact us for a non-binding online demo and let us show you what the QM process library can do for you! |

|